Making Sense of the Numbers - Understanding the Climbing Rope Rating System

- Posted on

- By Benoit Gosselin

- Posted in Gear, Ice Climbing, Rock Climbing

- 5

Out of all the climbing equipment, ropes are by far the piece of gear that has the most certifications and tests performed. This results in a lot of information and data printed on labels of climbing ropes. Sometimes, more information just makes our choice more confusing than it should be. In this article, we'll try to help you better understand all those numbers in order to enable you to buy the best rope for your needs.

All this confusion could explain the results of a couple of consumer surveys performed by US rope manufacturers in early 2000. They found that consumers ultimately bought ropes based on colors and sheath pattern and that the information found on labels was confusing and not helping in the decision making process. In my 20 years of working in the climbing industry, I have witnessed the same thing when people shop for a new climbing rope.

The first thing we need to establish is the difference between the 3 types of ropes. Secondly, we'll give a rough guideline of the forces a climber and their gear may be subjected to in a day of climbing. Then, we'll talk about the tests a climbing rope is put through and lastly, we will break down all of the data, certifications and information found on climbing rope packages to help you pick the best rope for your needs.

Three Types Of Dynamic Climbing Ropes

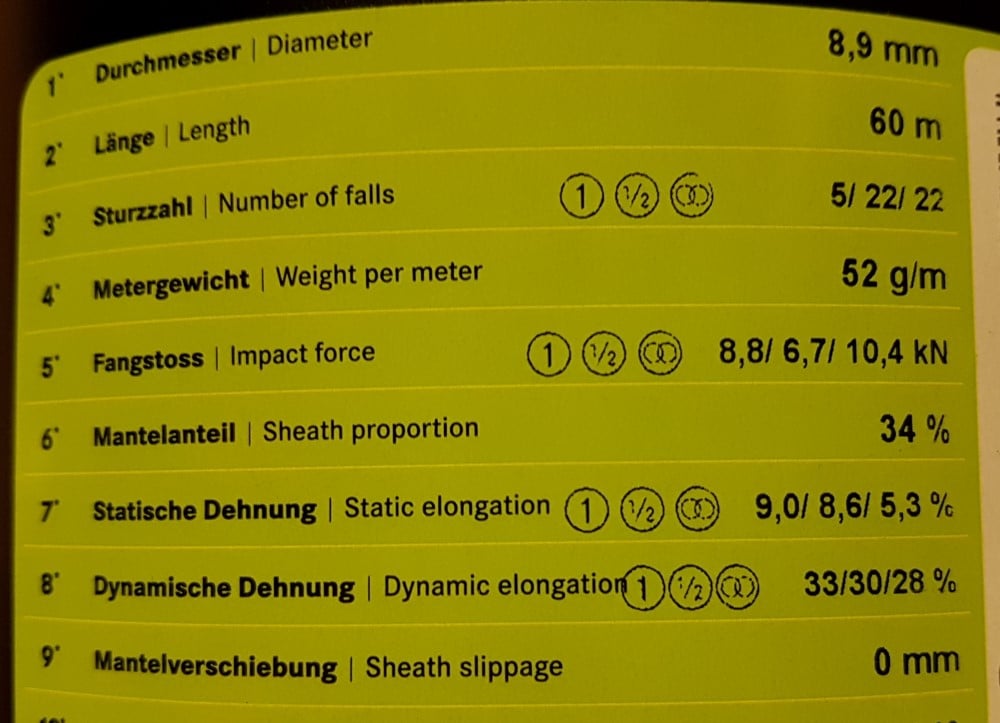

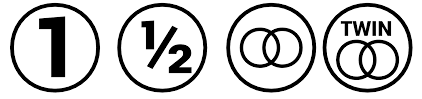

Dynamic ropes for climbing can be divided into three categories, each with their own strengths and intended uses: single, twin, and half.

Single Ropes

Single ropes are the most common and simplest to use. One rope is used in the system and is rated to hold multiple falls. With a single rope, the leader clips the rope in each piece of protection and the belayer only has one rope to manage. A belayer can also use an assisted braking belay device like the Petzl Grigri or Madrock Lifeguard, which can only accommodate a single rope. Single ropes are the best choice for the overwhelming majority of climbing, and depending on the diameter and features, can be used for trad, sport, ice, alpine, gym and big wall. The downside to a single rope system is the need for a second rope for full-length rappels and the lack of redundancy. Some wandering routes may require lots of long slings to mitigate rope drag, unless using a half rope system (more below.)

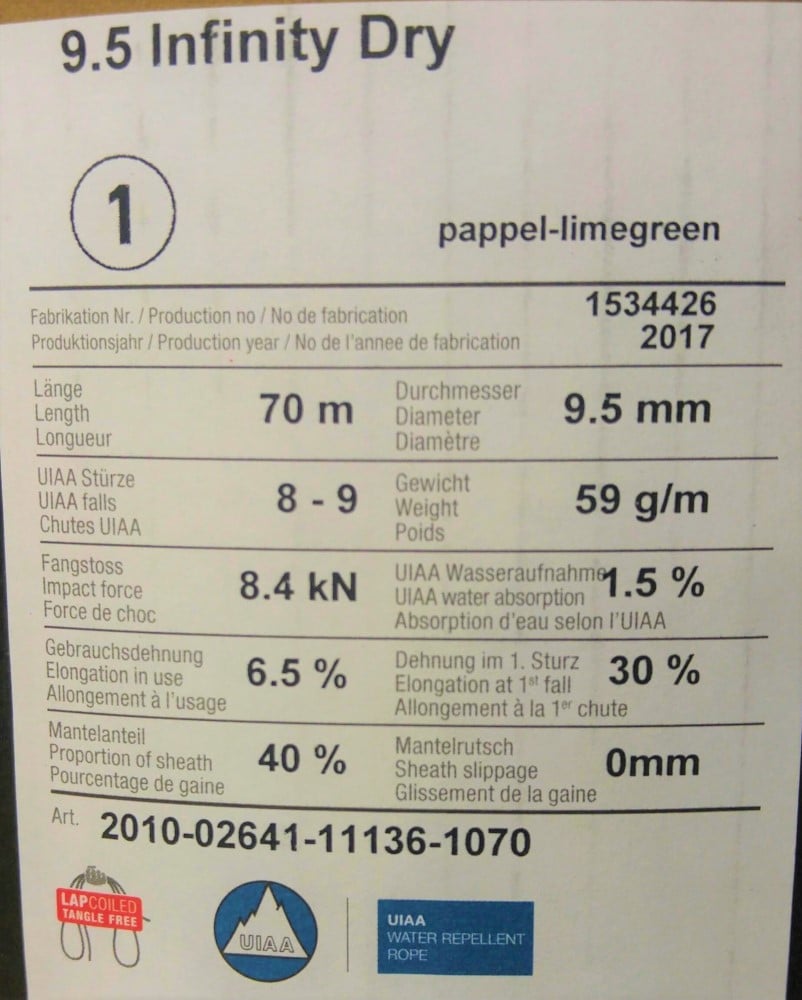

Single rated ropes will be denoted with a number one inside a circle and this will be found on the small tag at the ends of the rope, as well as on the packaging.

Twin Ropes

Twin ropes are the first of two double rope systems we will touch upon. The twin rope setup is designed to be used with two in tandem. The climber ties into both ropes and clip both ropes into each piece of protection, identically how one would with a single rope. This is advantageous because having two ropes enables the climber to have full-length rappels and provides added safety and redundancy in the event one rope is compromised.

Twin ropes are not designed to be used independently, meaning they must always be used as a pair. In North America, this is not a common system due to the inconvenience of clipping both ropes and durability issues associated with the thinner diameters. They are the lightest double rope setup, making them ideal for alpine climbing and are found in diameters as low as 6.9mm.

The symbol for twin ropes is an infinity symbol within a circle, occasionally with the word “twin” written above.

Half Ropes

A more commonly used, but increasingly complex rope method is the half rope system. As with Twins, in this set up both climbers are required to tie into both strands. Each strand of a half rope is rated to hold a fall on its own, albeit with a lower weight in tests (more below). They are also skinnier and lighter than single ropes, making them less durable and less likely to sustain repeated hard falls. In application, the leader will alternate clipping the two ropes, providing redundancy and reducing rope drag. This system is the most complicated to learn and can lead to hassles in rope management but is a great system for routes that require thoughtful protection.

Half ropes are easily identified by the fractional “half” symbol.

What is a Kilonewton (kN)?

In climbing, we utilize the kilonewton (kN) as our measure of force. This is an indication as to the amount of force being placed on the climber, belayer, and climbing system. So what is a kilonewton? The quick answer is that 1 kN is approximately 100kg, however, this omits is the influence of gravity on the load. Because gravity is an exponential equation, a heavier object moving faster will produce more force. If you remember your high school physics:

|

Force(F) = Mass(M) x Acceleration(A) F = 1kg x Gravity (9.81m/s) F = 1000g x 9.81m/s F = 9.81N F = 0.00981 kN |

For simplicity sake, we can state that if a 100kg climber is hanging from a rope, he is putting 1kN of force on the system. During a climbing lead fall, depending on the weight of the climber, the length of the fall and the amount of rope to absorb the impact, the climbing system can experience anywhere from 3-7kN. Which brings us to our second point: The fall factor.

What Is A Fall Factor?

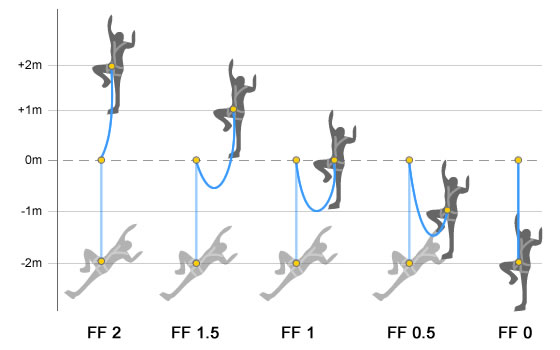

A fall factor (FF) is calculated by taking the distance of a fall, divided by the length of rope available to catch the fall of the lead climber (measured as the length of rope between the belay device of the belayer and the knot of the lead climber). This is often used as an indication of the severity of a climbing fall and is quantified between 0 and 2.

|

Fall Factor (FF) = Length Of Fall / Rope Length |

As seen in the image above, a climber weighting a rope is producing a FF 0, whereas a climber with two meters of rope who falls from the height of the anchor would produce a FF1.

|

Fall Factor (FF) = Length Of Fall / Rope Length FF=2m/2m FF=1 |

With the exception of via ferrata, a fall factor of 2 is the highest impact force we can produce while climbing (2 meters fall on only 1 meter of rope). This is often misunderstood because a lot of people assume a longer fall would automatically produce a higher impact force. It is, in fact, the relationship between the length of the fall vs the amount of rope available to catch the fall that matters.

Where Do The Numbers On A Rope Label Come From?

Most of the information printed on rope labels come from the certification requirements from the UIAA ( Union international des associations d'alpinisme). The UIAA established minimum standards and test protocols to ensure the safety and performance of personal protection equipment such as climbing ropes. Rope samples are sent by manufacturers to be tested at independent UIAA certified labs to make sure they meet those minimum requirements.

The tests are standardized for transparency and ease of comparison. To fully understand where the test numbers come from, let's examine the test used to produce this data.

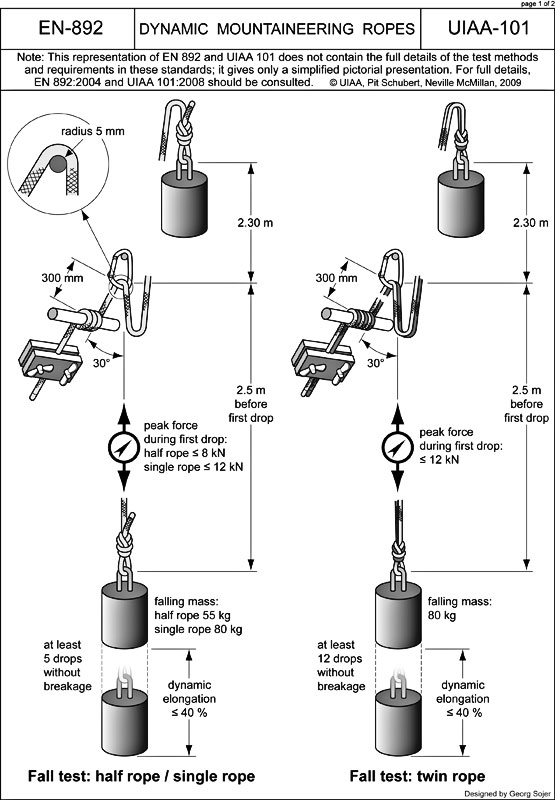

A mass is attached at the end of a rope sample.

The mass is then raised 2.3 meters above a quickdraw with an anchor positioned 30 cm below the quickdraw.

The fall factor used for this test is therefore 4.6 meters fall / 2.6 meter of rope = 1.77 ((2.3 X 2) / (2.3 + 0.30) =1.77)

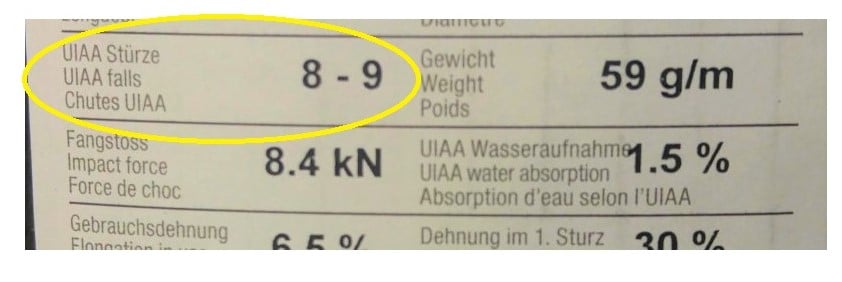

This fall is repeated until failure of the rope sample resulting in the "UIAA Falls" number seen on the label.

The mass used for this test is as follow:

- 80 kg for the single rope certification

- 55 kg on a single strand of rope for the half rope certification

- 80 kg on two strands of rope for the twin certification

Making Sense Of These Numbers

Impact Force

This is a very important information if you are planning on using the rope for ice, alpine or traditional climbing. The Impact Force (IF) is a measure of the elasticity of the rope, and consequently its ability to absorb the energy in a climbing fall. This can be interpreted as the amount of force your body would "feel" during the standardized test with a fall factor of 1.77. The higher the impact force, the more energy will be transmitted to the belay system and the associated protection. Anytime you might be relying on less than perfect protections, the lower the impact force the better, as this will create a soft catch and is less likely to put undue stress upon your protection. Care should be taken when using a rope with low impact force for top roping as these ropes tend to sometimes stretch more.

|

Single Rope |

Half Rope |

Twin Ropes (Pair) |

|

|

UIAA Maximum Impact Force |

12 kN |

8 kN |

12 kN |

Number Of Falls

This by far the most misunderstood information about climbing ropes. During this test, which is performed using the same method as Impact Force, ropes are subjected to sequential drops in a Fall Factor 1.77 until failure is achieved. This generates an unusually high amount of force and is extremely unlikely to be replicated in a real-world climbing situation.

Here's the minimum falls ropes need to withstand in order to pass the UIAA testing.

|

Single Rope |

Half Rope |

Twin Ropes (Pair) |

|

5 Falls |

5 Falls |

12 Falls |

Dynamic Elongation

Dynamic elongation is a finicky variable that plays close at hand to that of the Impact Force. Essentially, this is the length the rope stretches to produce the low impact forces we seek. While we want a low impact force, we don’t want a rope to stretch too far to achieve that, as it might put the climber at risk for stretching too far and hitting the ground or a ledge.

In the same test as the Number Of Falls test a weight is dropped and after the first 1.77 fall factor in the ultimate number of fall test, the difference between the actual traveled distance of the 80 kg mass and the theoretical distance (2.3 meters X 2) is expressed in percentage. According to the UIAA, the dynamic elongation should be no more than 40% for all classifications of ropes (single, double and twin).

|

Single Rope |

Half Rope |

Twin Ropes (Pair) |

|

|

UIAA Dynamic Elongation |

40% |

40% |

40% |

Static Elongation

Useful information mainly for top roping applications. The standard test is to tie a 5 kg mass to 1 meter of rope and then replace the 5 kg mass by 80 kg and measure the difference in stretch between the two masses. The result is expressed in percentage. The maximum static elongation for single ropes is 10% (10 cm on 1 meter of rope), for half rope 12% on a single strand and for twin ropes 12% on both strands.

This is important to think about if you’re belaying a second on a multipitch and they ask for a take, as this could give you an indication as to how far they will settle into the rope.

|

Single Rope |

Half Rope |

Twin Ropes (Pair) |

|

|

UIAA Static Elongation |

10% |

12% |

12% |

Rope Diameter

This one is pretty self-explanatory, this is the diameter of the rope expressed in mm. Something to note is the tolerance allowed by the UIAA in expressing the diameter on the label. Manufacturers are allowed to advertise 0.3mm above or below the actual diameter measurement. A 9.5 mm labeled rope might, in fact, be anywhere between 9.2mm and 9.8 mm. This leeway is used by rope manufacturer to strategically position their ropes on the market.

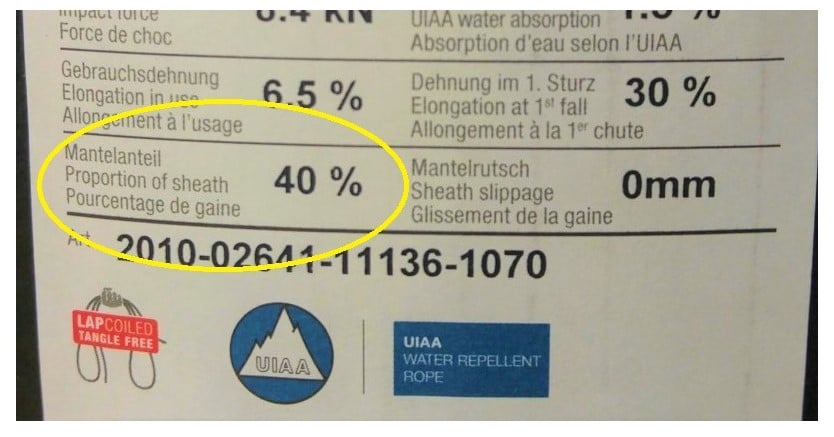

Weight

This is expressed in grams per meter. A lighter weight rope will be appreciated on arduous approaches or long climbs where you’re trailing substantial rope weight. This can often (but not always) give you a rough idea of the durability of the rope. As with anything, usually the lighter we go, the less durable the rope will be in the long term. Weight can also be the best way to compare two or more similar ropes from different brands as the diameter can sometimes be misleading.

Sheath Percentage

The sheath percentage is often a better indicator of durability. This is the ratio of sheath vs core expressed in percentage. Not all manufacturers publish this information but it is useful for determining how abrasion resistant a rope is. Thicker sheath usually translates into a more durable rope. I am using the word "usually" because other factors such as the number of threads and the type of weave will also affect how durable the rope will be.

Sheath slippage

Climbing ropes are made up of two components, a core and a sheath. The core usually handles the mechanical properties of the rope, the sheath is there to protect the core against abrasion and UV rays. Every manufacturer have a different process to ensure a durable bond between the two components. In the UIAA test, a 2-meter sample of rope is run back and forth through a device that pinches the rope. After 5 cycles, there should be no more than 20 mm separation between the core and sheath.

UIAA Water Repellent Certified

After 10 years of research, the UIAA finally came up with a standardized test for dry treated ropes. A sample of rope is lightly abraded to simulate some wear on the sheath. Water is then run against the sample for 15 minutes at a rate of 2 liters per minute on a 30-degree plane. After the elapsed time the rope sample is put on a scale and should have absorbed no more than 5% of its original weight. In comparison, a non-dry treated rope will absorb water up to 50% of its weight. Before this standard was implemented, "Dry" labeled ropes have been found to absorb anywhere between 20% and 40% of their weight in water.

Having a dry rope is a non-negotiable for ice and alpine climbing, as it is a near certainty that the rope will become wet during the course of the day, but it is debatable whether this is required for general summer use.

Middle mark

A useful feature for easily finding the half point of a rope, but keep in mind that according to the UIAA the marked midpoint must be within 1 meter of the actual halfway point of the rope. The two methods to signal the halfway point are a change of pattern and/or the introduction of a new color strand in the sheath or a simple black ink mark. The black ink is more cost effective but over time might become less visible especially on dark colored ropes.

In conclusion, understanding the numbers on labels are important and should sway your decision based on the type of climbing you will be doing with the rope. The most important point to understand is that a lot of time, money, and energy has been invested by the UIAA and all rope manufacturers to ensure that the ropes you'll find at your local climbing shop have huge safety margin built into them. The biggest safety factor will always rest on our shoulders, the climbers. It is our responsibility to choose a rope and use it according to its specification (single, half, twin) and to take proper care of the piece of equipment that saves our ass so many times.

If you have any questions or want clarification on any of the information found here, please comment below or come into Vertical Addiction and chat with one of our great staff members. We all love nerding out over this stuff!

|

Climbing is dangerous and posses inherent risk. It is your responsibility to seek proper instruction from qualified professionals to learn the necessary skills to participate in any of the activities described herein. The information found here is for entertainment and general information purposes only and does not constitute advice, nor is it intended to be educational in any way. |

Hello Val,

For the recreational side of personal fall protection, I believe the UIAA is the only one. When it comes to working safety at height, most countries have their own certification body, like CE or CSA for instance.

Is the UIAA the only federation that does safety rating on ropes and other climbing equipment?

Hi Ken, excellent question! Half ropes are designed to be used in tandem. With the ropes separated, it is true that you may be falling primarily on a single strand, however as the rope stretches, the second strand will absorb a portion of the energy. The theory here is that it doesn't take as much initial force to begin catching the fall, resulting in a lower impact force being placed on the piece you're falling on. Also for this reason, if you were to use a pair of single rated ropes (tested with 80kg) as halves, more force would be required to stretch them, resulting in a harder catch and greater force on your gear.

For something with increased versatility, there are a number of relatively new ropes on the market that are triple rated (single, half, twin), enabling you to alter your protection strategy as needed.

"Tests done at the time by Pit Schubert of the DAV (German Alpine Club) showed that any half rope that would withstand 5 UIAA test falls with a 55 kg test mass would also withstand one UIAA test fall with the 80kg mass. " from http://www.supertopo.com/climbing/thread.php?topic_id=833631&tn=165

Thanks for this article. I've always wondered why half ropes are tested with a lower mass than a single rope? In the field you would clip into one rope at the time as you say in the article, and therefore fall on one rope at the time. It would therefore seem logic to me that the mass in the test should be the same as for a single rope. Can you shed any light on this for me?